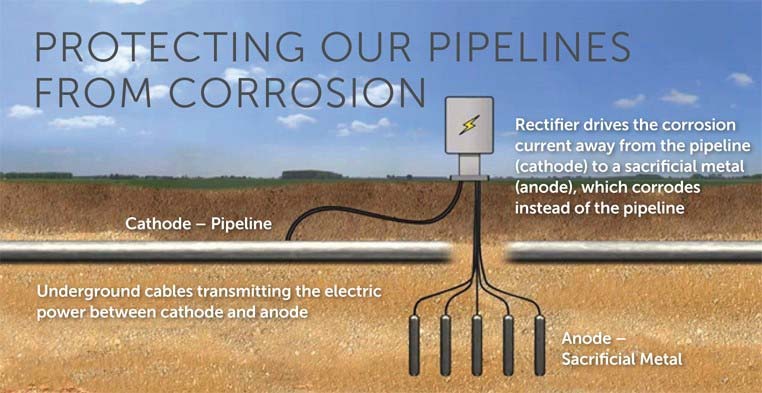

Cathodic Protection

Cathodic protection (CP) is a method of protecting metal structures from corrosion, commonly called rust, which is the degradation of a metal material caused by a reaction with its environment. If the metal components of Pipelines, Buried Piping, Underground and Surface Storage Tank (UST & SST) Systems are not protected, they will eventually corrode and leak, causing contamination of soil, groundwater, and surface water by petroleum and other hazardous substances.

When is Cathodic Protection Required?

In general, any metal tanks and metal appurtenances such as piping, valves, and connectors that are in contact with soil and routinely contain a regulated substance must have CP. Stainless steel components such as stainless steel-encased flex connectors can still be subject to corrosion and do require CP if they are in contact with soil. Tanks and piping that are double-walled require CP when the outer wall is made of metal.

Structure to be Protected.

- LNG Storage Tanks

- Crude Oil Storage Tanks

- Water Storage Tanks

- Petroleum Storage Tanks (DPK, AGO, PMS & Jet Fuel)

- LPG Storage Tanks

- Diesel, Fuel and Kerosine Underground Filling Station Tanks

- Gas Tanks

- Pipeline and Buried Piping’s

- Reinforcing steel in concrete structures

- Heat Exchangers

- Marine Piles

- Sheet Pile Walls

- Other Metallic Structures

Corrosion – This is one of the most common reasons behind the failure of a storage tank, vessels and pipeline. Studies have revealed that corrosion causes tanks, vessels and pipeline to rupture from inside, and ultimately damages the entire structure.

Corroded and leaking aboveground Storage Tank as a result of not protecting the tank with Cathodic Protection System

Lack of Cathodic Protection System – The entire tank and Pipe system is at risk of cracks, leaks, corrosion or other physical damage if it’s not well-protected. Unarguably, this is one of the major causes of tank and pipe failures.

Structural Failure – Industry experts have revealed that corroding of pipes due to mechanical breakdown is another major cause of tank failure. They further add that the corrosive effect of acids and other chemicals on the inner surfaces of the pipe gradually leads to leakage. This again leads to mechanical failure if left unattended.

What’re your Cathodic Protection needs?

Talk to us about your requirements and a representative will reach out to you for an initial assessment of the project.